SmartLi

In the era of Industry 4.0, efficient infrastructure control is essential to maximise productivity and minimise operational costs.

SmartLi is an intelligent management system for lighting and other electrical points, providing industrial facilities with the technology to optimise operations, reduce energy consumption and improve working conditions.

What is SmartLi?

SmartLi is an integrated platform for managing electrical devices, centralising the control of lighting, gates, sensors, blinds and on/off devices in a single intuitive interface. Accessible via mobile app or web browser, it allows management, monitoring and control of all devices in real time, even remotely.

Through a scalable approach, SmartLi adapts to facilities of any size - from small manufacturing units to large industrial complexes and municipalities.

Main system components

Points

Each point represents an individual device. SmartLi offers multiple management types for each point:

On/Off: Simple power on/off control

Percentage: Adjusts device state by percentage (e.g., gate 80% open)

Dimming: Adjusts light intensity (0-100%)

RGB: Colour selection from a matrix

She Change - Anémona. RGB lighting managed via SmartLi.

Groups

Groups aggregate multiple points of the same type, allowing simultaneous actions on several devices. Examples:

Turn all points on or off

Activate or deactivate motion mode for sensors

Control lighting intensity according to ambient light

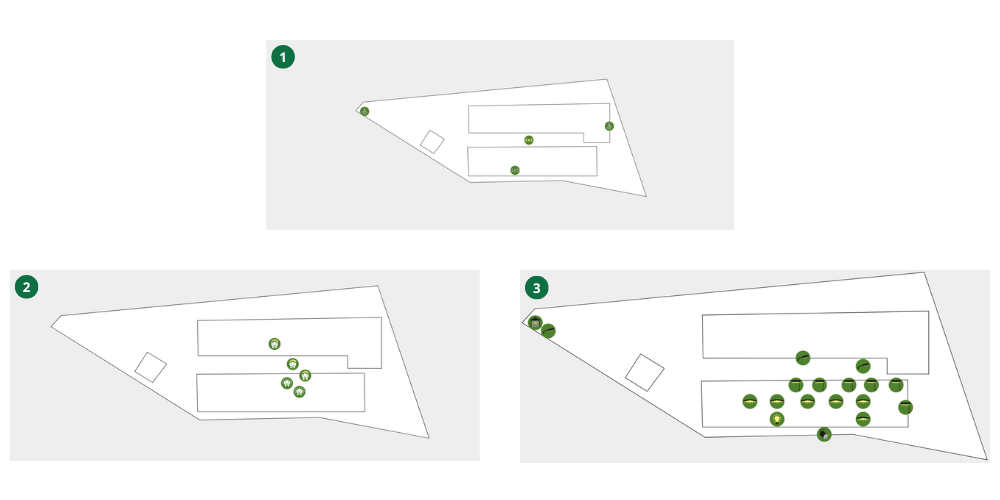

Layouts

Interactive graphical representation of the facility layout showing the location and status of all points and groups.

Scenarios

Set of automated operations that can act on points or groups, manually or automatically. Scenarios can be scheduled for specific days, times, or seasons.

Practical examples of industrial scenarios:

"Factory Opening": Opens gates, activates lighting in common areas and opens blinds

"Closing": Switches off non-essential lighting and turns on emergency lighting

"Peak Production": Optimises lighting according to high production hours

Sensors

Centralised management of all facility sensors:

Motion sensors

Light sensors

Battery level sensors

On/off sensors

The platform allows real-time visualisation, configuration and optimisation of each sensor.

1. Sensors | 2. Groups | 3. Points

Specific Advantages for Industrial Applications

1. Maintenance cost reduction

SmartLi provides instant information about each device, enabling problems to be diagnosed before becoming critical through intelligent maintenance features, such as continuous equipment monitoring.

This diagnostic capability reduces unplanned downtime, extends equipment lifespan, and significantly lowers maintenance costs. In manufacturing environments, each hour of unexpected downtime represents a major productivity loss - SmartLi helps prevent it.

2. Adaptive lighting

SmartLi's Adaptive Light concept transforms how lighting is used in industrial environments.

The platform automatically adjusts light intensity in real time according to the needs of each area, based on factors like ambient light and time of day.

Direct benefits:

Reduced energy waste: Light only where and when needed

Extended lamp life: Optimised usage reduces on/off cycles

Improved visual comfort: Ideal lighting for each task (crucial for precision tasks)

Enhanced safety: Identifies areas with inadequate lighting

In 24/7 operations, adaptive lighting can result in significant energy savings while maintaining safety and productivity standards.

3. Automation and centralised control

Fragmented management of electrical equipment is inefficient. SmartLi offers:

Centralised control of the entire electrical infrastructure from a single platform

Automated processes without continuous manual intervention

Scalability: system grows with the facility, easily integrating new devices

Full customisation: scenarios and schedules tailored to each location's needs

Operational flexibility: quick adjustments for production or occupancy changes

Remote control of lighting and devices via web or mobile app

Multiple Communication Options

SmartLi was developed for communication flexibility.

Connectivity options:

Wi-Fi: For network-covered facilities

Ethernet: Dedicated, stable connection in critical environments

Mobile network: For remote or decentralised sites

Supported device protocols:

SmartLi gateway communicates with devices using multiple protocols, including: ZigBee, DALI, RS485, RS232.

Intuitive and accessible interface

User experience is central to the SmartLi platform design.

Facility map view: Interactive map with real-time status

Three-level navigation: Sensors → Groups → Points

Granular control: Individual or group device management

Detailed reports: Complete operational data analysis

Optimised mobile interface: Full control in the palm of your hand

Practical applications

Factories

Challenges: Large areas, multiple shifts, continuous operations, and safety

SmartLi solution:

- Lighting adapted to each shift and work area

- Scenario automation for production changes

- Preventive lighting monitoring

- Significant energy cost reduction in 24/7 operations

Warehouses and Distribution Centres

Challenges: Variable occupancy, large areas, and logistic efficiency

SmartLi solution:

-

Automatic lighting based on motion and occupancy

-

Management of loading/unloading zones with optimised light

-

Reduced energy in temporarily empty areas

-

Enhanced safety in high storage areas

Municipal infrastructures and industrial parks

Challenges: Multiple buildings, seasonal variation, distributed management

SmartLi solution:

-

Centralised management

-

Reduced energy costs

-

Automated seasonal scenarios

Safety and Compliance

SmartLi was developed to strict safety standards:

Secure authentication: User profile-based access control

Data encryption: Protection of sensitive information

Regulatory compliance: Meets data protection standards

Conclusion

SmartLi represents the natural evolution of industrial infrastructure management. By centralising control of lighting and electrical devices, it provides:

-

Operational cost reduction through increased energy efficiency

-

Preventive maintenance capabilities

-

Enhanced safety with optimised lighting and regulatory compliance

-

Scalability - grows with your facility

-

User-friendly experience with full web or mobile control

Discover how SmartLi can transform your industrial facility. For a personalised analysis and demonstration of the system adapted to your specific needs, contact our team.